Warehouses often need help with storage space, especially when inventory keeps growing. While this is good for business, it may put pressure on existing systems inhibiting productivity. What solution allows for optimum space usage while adding more upward storage space? A rack-clad warehouse. Clad racking is not new. Various industries have benefitted from this phenomenon to increase storage space.

This warehouse type uses racking and shelving systems as the foundation for the entire structure. A rack-clad warehouse offers more than space maximization but also cost savings. To better understand what these systems are and their benefits, here is a comprehensive guide with the details.

What Is a Rack-Clad Warehouse?

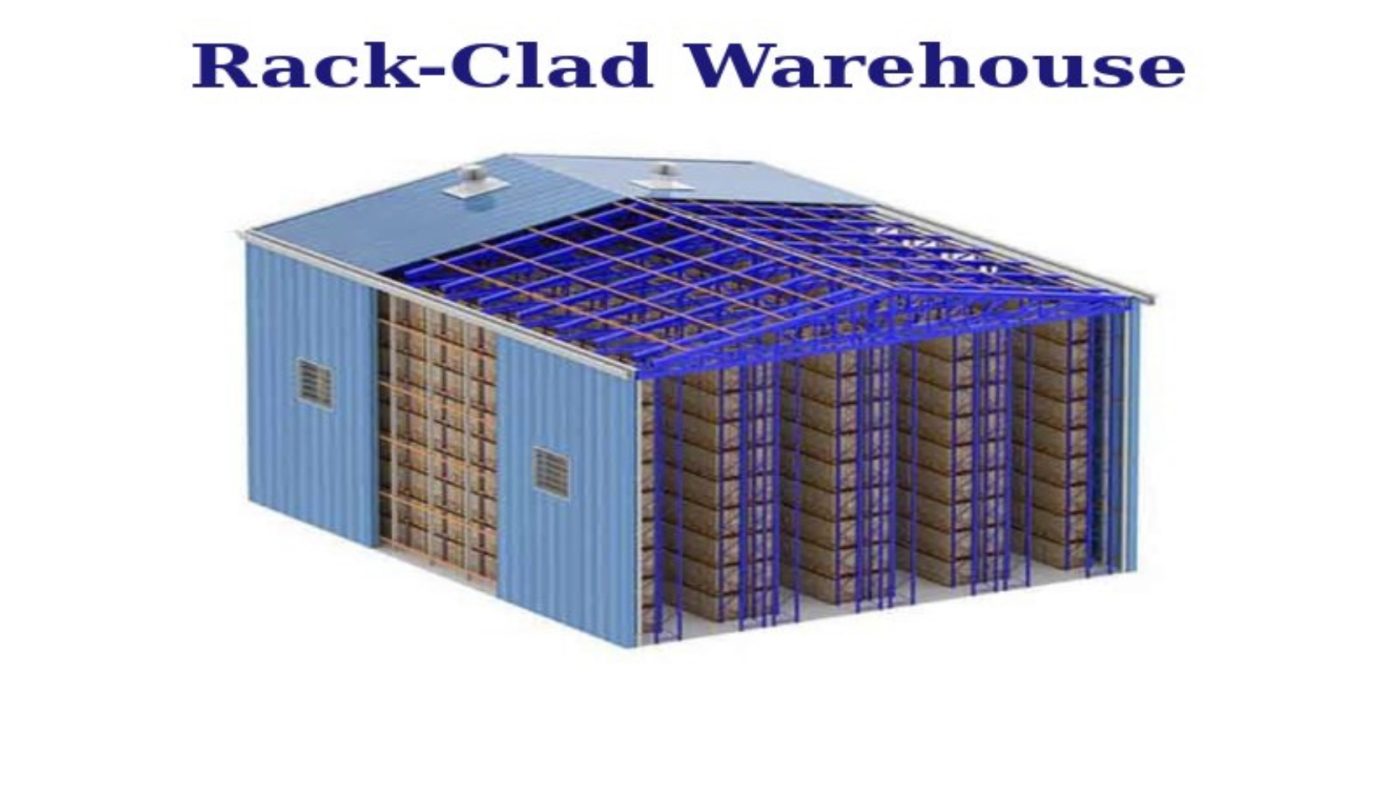

A rack-clad or clad racking is a temporary warehouse using an existing racking as a foundation for the building. After installing the racking, installers fix the cladding on the exterior for a strong, weatherproof structure. Rack-clad buildings are increasingly becoming popular because they expand warehouse storage without moving to new locations.

Building more storage space upward increases capacity while minimizing costs. Considering these structures extend tens of meters into the sky, they are challenging to build. They require specialized equipment to put together and create a warehouse.

Basic Components of Rack-Clad Warehouses

The construction of a rack-clad warehouse is simple. The building comprises racks supporting the upper trusses, side profiles and roof girders. The structure also supports the handling equipment, either fixed or free-moving.

The roof of a rack-clad warehouse combines steel panels welded or bolted into a frame mounted on the pallet-racking structure. The frame can either use a sloping gable or shed roof to conform to climatic conditions.

The walls on rack-clad warehouses have panels attached in three different ways:

· Fixed directly to the racking units

· Fixed into an intermediate frame that attaches to the structure

· Fixed onto an intermediate frame attached to an independent frame

When building rack-clad warehouse walls, there are certain factors to consider, like the height, average wind strength, climatic conditions, and materials used for building the walls.

Why Are Rack-Clad Warehouses Popular?

Racking warehouse systems are popular in racking and shelving because they save space. The space efficiency of a rack-clad is unmatched, considering storage racks form the entire building. These robust systems are strong enough for dense storage, with many upright rack columns distributing load weight. These structures can withstand heavy rainfall, strong winds, heat, and seismic movements.

Advantages Of A Rack-Clad Warehouse

Operators build the entire warehouse with racks that take up the floor space. There are no intermediate pillars that affect space distribution.

Similar to the surface area, a temporary warehouse only extends to the required height. The upper trusses and girders are shorter, and the racks can support them directly.

Clad racking warehouses can be built to any height, depending on the local regulations and handling needs. These structures can extend over 40 meters high, especially for complex construction.

Building a rack-clad requires only a concrete slab for uniform distribution of the force exerted by the racks. Besides the concrete, the other requirement is a racking system and walls. After building the slab, you can progressively and concurrently install the cladding and racks.

Building a clad racking warehouse is cheaper than building a traditional warehouse. Warehouse managers can save more money on construction and operation costs compared to operating a warehouse. A higher temporary warehouse offers more storage space, improving business operations.

Due to the simple nature of the clad racking system, taking it down is also easier. When operations change, the components are easily removable, considering they are either bolted or pre-assembled.

Factors to Consider When Using Clad Racking

Installing a rack-clad is dangerous, and managers must pay attention to health and safety. Evaluation of all situations is crucial to ensure that the structural integrity is up to standards. Working jointly with warehouse management solutions to mitigate the risks is advised. Warehouse management ensures the building gets close attention around the clock.

The base plates on the racking and shelving systems are subject to forces that add more pressure to the floor. Stress calculations are compulsory to guarantee the safety of storage systems and products after construction. Depending on the height of the clad racking, wind can affect the productivity of the warehouse and possibly halt the project.

When building a rack-clad warehouse less than 12 meters high, non-automated systems are ideal for drive-in and push-back pallets. Systems above this height can use single or double-deep racking, which allows compatibility with portable systems. Clad racking over 15 meters high require automatic handling machines.

Rack-clad warehouses are easy to integrate with existing traditional storage systems to increase storage efficiency. Businesses with varying storage needs should consider these clad racking to save on costs and utilize the available space. Clad racks lessen errors in loading and unloading racks and enhance overall warehouse efficiency.